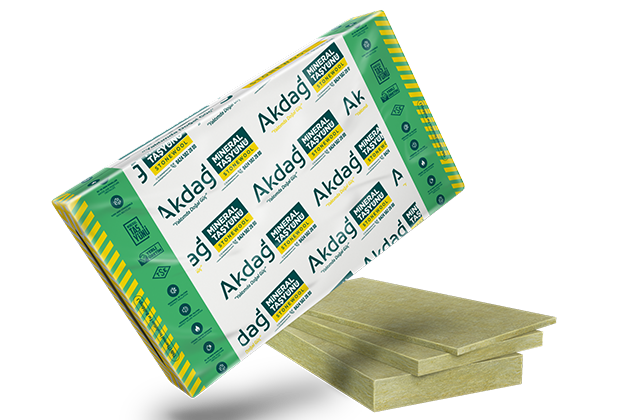

Akdağ Mineral Stonewool

Furnace Board

Product Features and Usage Areas

Akdağ Mineral Stonewool Furnace Boards are Stonewool boards that are used for heat preservation in household electric ovens, industrial ovens, paint ovens and can be produced with bakelite (formaldehyde) or without bakelite (biobase) depending on the desired dimensions and usage areas according to the manufacturer’s demand.

| Product Characteristics | ||||||

|---|---|---|---|---|---|---|

| Technical Characteristics | Symbol | Indicator | Unit | Declared Value | Tolerance | Standard |

| Material | MW | MW | - | Mineralwool | - | TS EN 13162 |

| Density / D | - | ρ | kg/m3 | 30 | 40 | 50 | ± % 10 | TS EN 1602 |

| Lenght / l | l | l | mm | 1200 (can be evaluated at the request of the manufacturer) | ± % 2 | TS EN 822 |

| Width / b | b | b | mm | 600 (can be evaluated at the request of the manufacturer) | ± % 1,5 | TS EN 1822 |

| Thermal Condictivity | λD | - | W/mK | max 0,037 | - | TS EN 12939/12667 |

| Thermal Resistance / Rd | RD | - | m²K/W | 0,83 | 1,11 | 1,39 | - | TS EN 13162 |

| Thickness / d | dN | dN | mm | 30 | 40 | 50 | - | TS EN 823 |

| Class for Thickness Tolerances | Tİ | - | mm | 'T4 | -%3 or -3 mm * +%5 or +5mm * |

TS EN 823 |

| Dimensional Stability | DS(70-) | ∆Ɛd | % | max 1 | - | TS EN 1604 |

| Water Vapour Permeability / MU | MU | µ | - | 1 | - | TS EN 12086 |

| Fire Reaction Class | - | RtF | - | A1 | - | TS EN 13501 |

| Air Flow Resistance /Afr | Afr | Afr | - | NPD | - | TS EN 29053 |

| Flatness / Smax | Smax | Smax | mm | S6 - max 6 mm | - | TS EN 825 |

| Squareness / Sb | Sb | Sb | mm/m | S5 - max 5 mm/m | - | TS EN 824 |

| Short Term Water Absorption / WS | WP | WS | kg/m² | ≤1 | - | TS EN 1609 |

| Long Term Water Absorption / WL(P) | WLP | WL(P) | kg/m² | ≤3 | - | TS EN 12087 |

| Max. Usage Temperature | - | - | 0C | '+750 | - | - |

| Packaging Material | - | - | - | PE Film | - | - |

| Covering /td> | - | - | - | Uncoated | - | - |

Download Product Catalogue

Download Product Catalogue